Cheesecake Energy Ltd (CEL), University of Nottingham, UK-based energy storage spin-out has raised £3.5 million (US$4.2 million) in pre-series A funding. The round was led by BGF – the UK and Ireland’s most active investor – with support from Perivoli Innovations and private investors including former Jaguar chair, Sir John Egan.

The funds will be used to grow the CEL team, begin pilot deployments of the company’s technology, and build partnerships with potential manufacturing and distribution partners around the world.

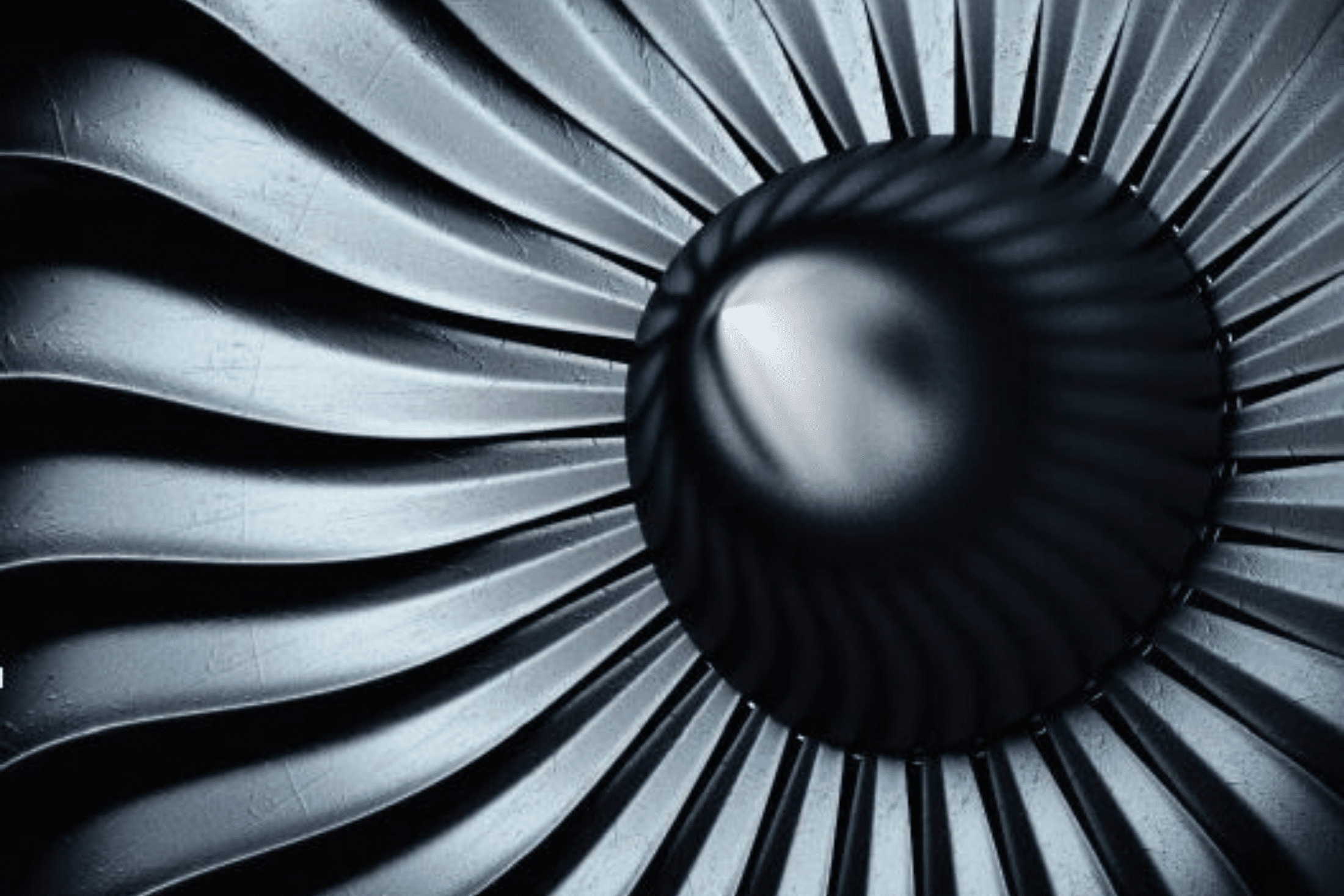

The company’s unique eTanker technology stores electricity in the form of heat and compressed air. To store the energy, electric motors are used to drive compressors, which deliver high pressure air & heat into storage units. When the electricity is required, the high-pressure air and heat is passed back through the same compressor, now working as an expander, which turns a generator to produce electricity. With its simple raw materials and longer life, the eTanker will displace lithium-ion batteries in a wide range of static applications, from industry and agriculture to transport and renewable generation.

“Compared with battery alternatives, our eTanker solution is lower cost and much more sustainable, with no rare or toxic materials and with a design that can be fully recycled at the end of its 20-year plus life,” said CEL co-founder and CCO, Mike Simpson. “Our system stores much of the energy as heat in inert rock in a way that is passively safe, avoiding the fire risk faced by some battery technologies.”

Employing circular economy principles, CEL converts truck engines into zero-emission electrical power-conversion machines for putting energy into and out of storage. Its technology brings together the low cost of thermal storage with the long life and robustness of a mechanical system, all in a modular containerised package.

Commenting on the funding, CEL CEO Paul Harris said: “We are pleased to have completed this funding round, which will enable us to accelerate the development of our technology, to deploy pilot projects and bring our novel, sustainable energy storage to market. We are looking forward to working with our visionary investor, BGF, and are grateful for the continued support from our existing investors led by Perivoli Innovations.”

Since 2011, BGF has backed a range of early-stage and growth businesses involved in the field of Climate Tech, everything from fuel cells to sustainable battery solutions and energy-efficient buildings. The CEL funding round takes the total amount invested by BGF in this field to £230 million.

Dennis Atkinson, investor at BGF, said: “We see huge potential for CEL’s technology and expect it to be a global leader in the energy transition from its base in the Midlands. The UK is a hotbed of innovation in this space, and it is vital that the investment ecosystem is supporting entrepreneurs and innovators to drive growth and development across key areas in the fight against climate change. We share the ambition and mission of the CEL team and look forward to helping them achieve it.”